Tuesday 1 July 2014: Construction Day 10 dawns with some drizzle after a Niagara end to June overnight with 29mm, bringing the June total rainfall to 130mm, more than 20% lower than for May. Strange – I expected it would have been a lot wetter… Since the Winter Solstice less than a fortnight ago, our days are starting to lengthen once more, albeit at a slow rate… Summer is ahead!

(Above): Builder John and his men arrive to be greeted by a couple of heavy Reikorangi downpours, and they start erecting their gazebo just behind the garage. This is not for picnicking, but rather as an undercover carpentry shop, lunch-time canteen and to keep their power tools, electronics and themselves a bit drier during showers.

Five minutes later, Ma Nature indicating that she would not be beaten by a lowly gazebo from lowly mankind, summoned a couple of well-blown gusts and almost lifted it like tiny balsa aircraft over the adjacent trellis fence.

Intermission: balsa… Presumably they still make model planes out of balsa wood, and not exclusively plastic? As a pre-teen, I remember that balsa was the preferred material (I guess they had yet to develop the plastic technology in the 50’s). Until now, I have never bothered to research balsa. Perhaps you have not, either?

There is no such thing as entire forests of balsa trees. They grow singly or in very small, widely scattered groups in the jungle. For hundreds of years, balsa was actually considered a weed tree. They reproduce by growing hundreds of long seed pods, which eventually open up and, with the help of the wind, scatter thousands of new seeds over a large area of the jungle. Each seed is airborne on its own small wisp of down, similar to the way dandelion seeds spread. The seeds eventually fall to the ground and are covered by the litter of the jungle. There they lay and accumulate until one day there is an opening in the jungle canopy large enough for the sun's rays to strike the jungle floor and start the seeds growing.

Balsa trees grow very rapidly (like all pesky weeds). Six months after germination, the tree is about 40mm in diameter and between 3 and 3.5 metres tall. In 6 to 10 years the tree is ready for cutting, having reached a height of 20 to 30 metres tall and a diameter of 300mm to 1.2 metres. If left to continue growing, the new wood being grown on the outside layers becomes very hard and the tree begins to rot in the centre.

Unharvested, a balsa tree may grow to a diameter of 2 metres or more, but very little usable lumber can be obtained from a tree of this size. The balsa leaf is similar in shape to a grape leaf, only a lot bigger. When the tree is young, these leaves measure a much as four feet across. They become progressively smaller as the tree grows older, until they are about 200mm across. Balsa is one of the few trees in the jungle which has a simple leaf shape. This fact alone makes it stand out in the jungle.

End of Intermission…

(Above): Holes at 600mm centres are drilled into the foundation of the existing structure for the reinforcing steel tie rods, as required by the Council. At the corner is the Lufkin laser level, against which all points in the planned concrete slab are measured.

Next job on the list was to fit and secure the waterproofing membrane over the hardfill.

(Above) John’s son fitting the height-extended ply boards to the dressing room wall, while John and an assistant fit the damp-proofing around the plumbing waste pipes.

(Above): The membrane in place and secured in Strawberry Lane. This will be the new access corridor. Each individual sheet is stuck to its neighbour with adhesive waterproof tape, much like the electrical insulation tape that I’m accustomed to.

(Above): John explaining to his son about some detail along the bedroom wall. The bit in the foreground is the sitting room corner.

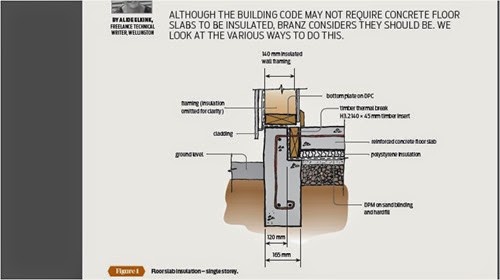

Next, the structural reinforcing steel bars are placed along the outer foundation trenches, followed by the polystyrene foam, which will assist in reducing the loss of heat through the floors. On top of the polystyrene comes the reinforcing steel grids, and fixed into place.

(Above): I see that the insulation website maintains, “…Although the building code may not require concrete floor slabs to be insulated, BRANZ considers they should...” [BRANZ is the acronym for Building Research Association of New Zealand]

(Above): Carefully placing the last sheet of reinforcing grid on the bedroom floor.

(Above): General view of the entire floor now covered with reinforcing steel grid.

The main jobs that remain before concrete may be poured is (1) the installation of reinforcing steel along the outer edge foundations, (2) the boxing and reinforcement of the three roof support pillars on the west side of the bedroom, and, possibly, (3) the removal of the dining-room window and and the catflap window, which needs to be relocated into the extended Strawberry Lane.

No comments:

Post a Comment